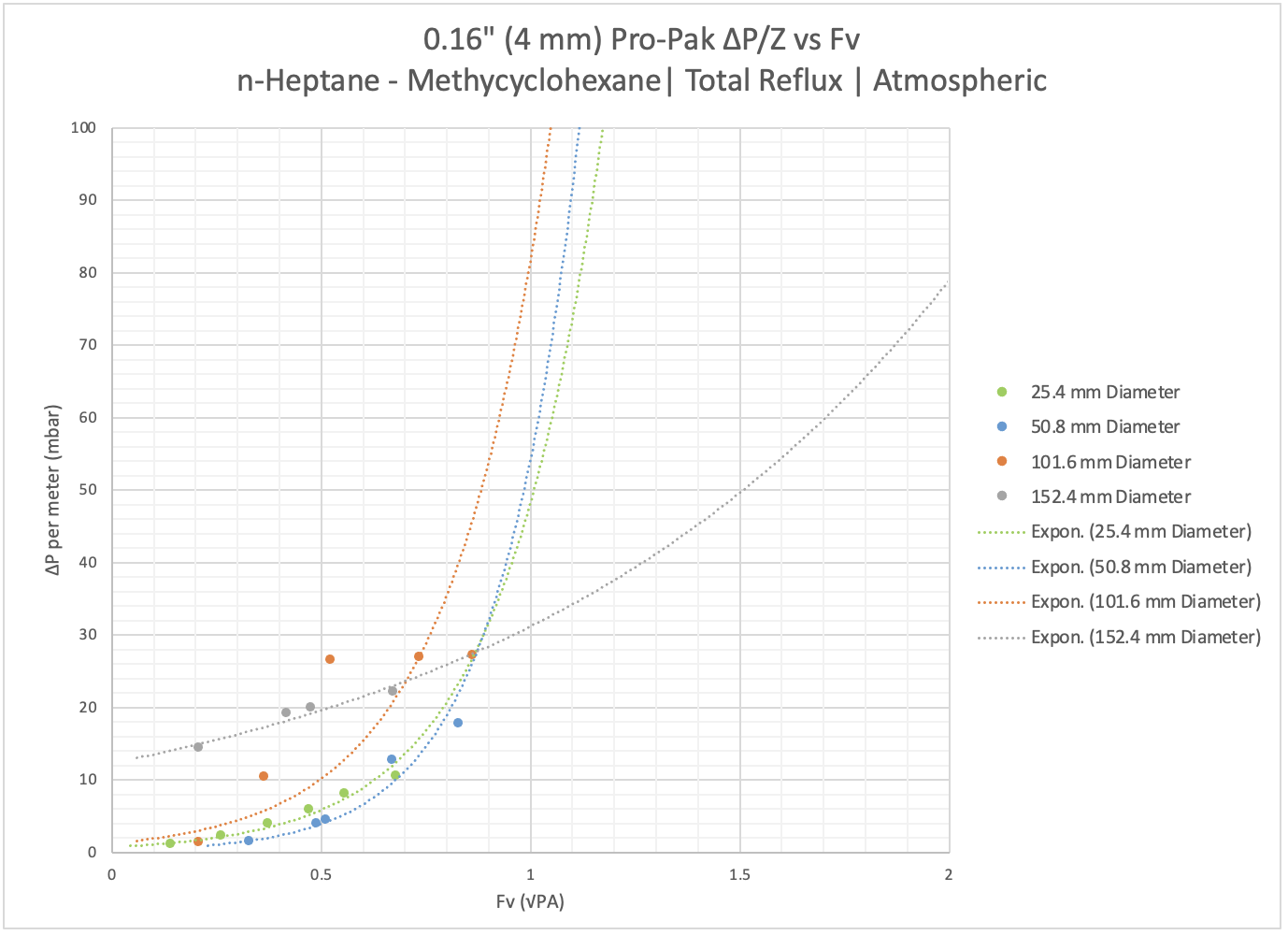

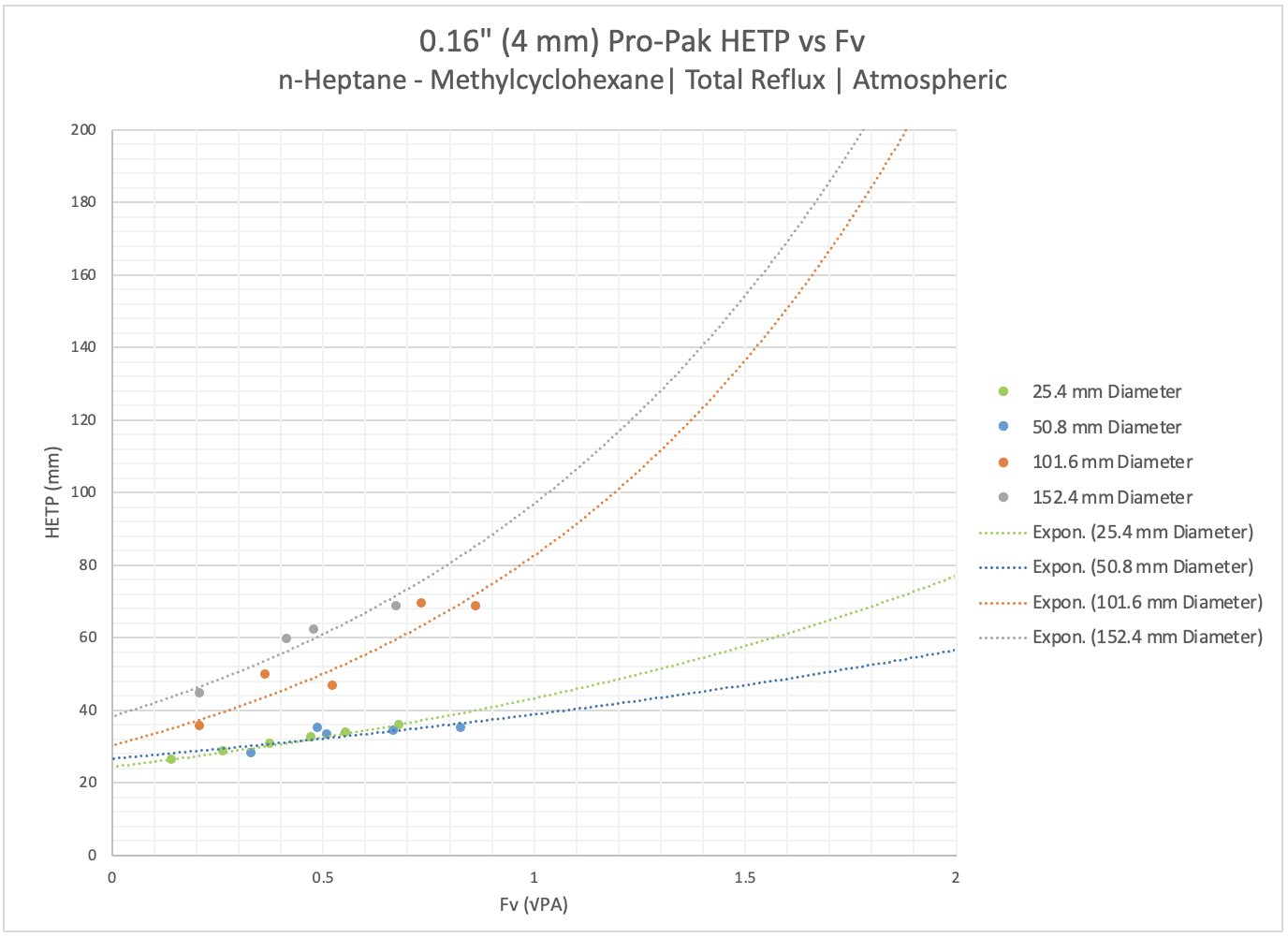

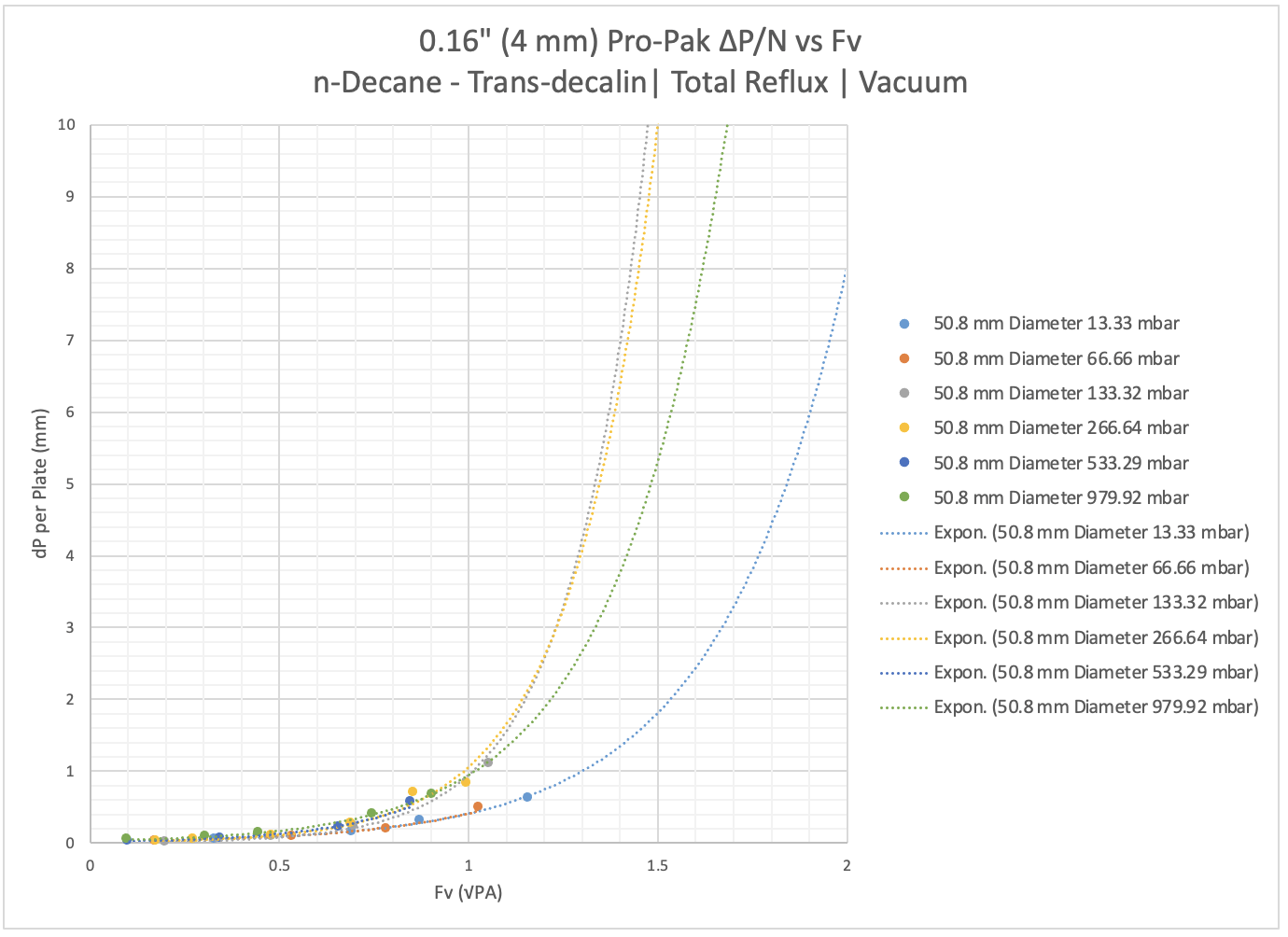

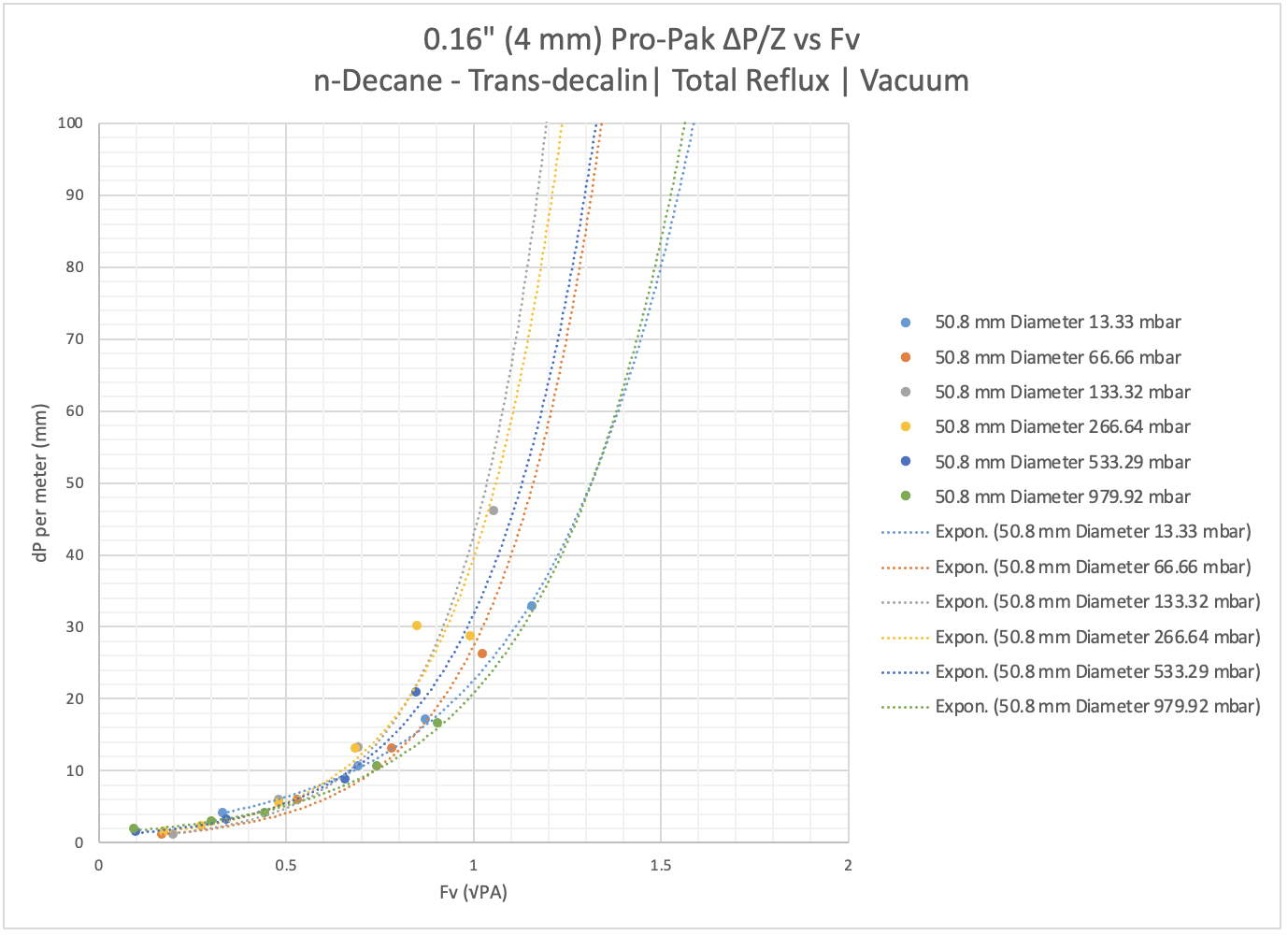

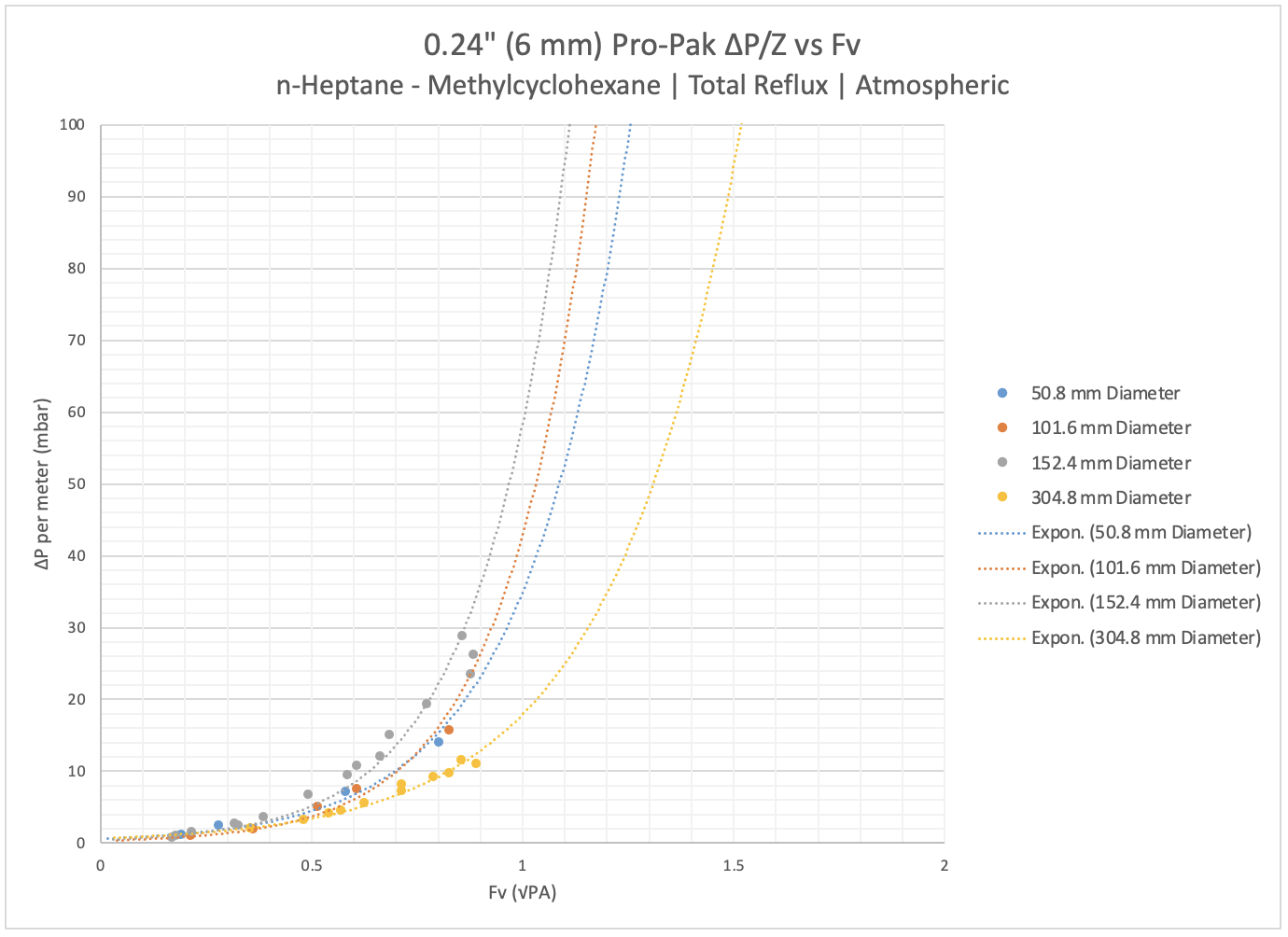

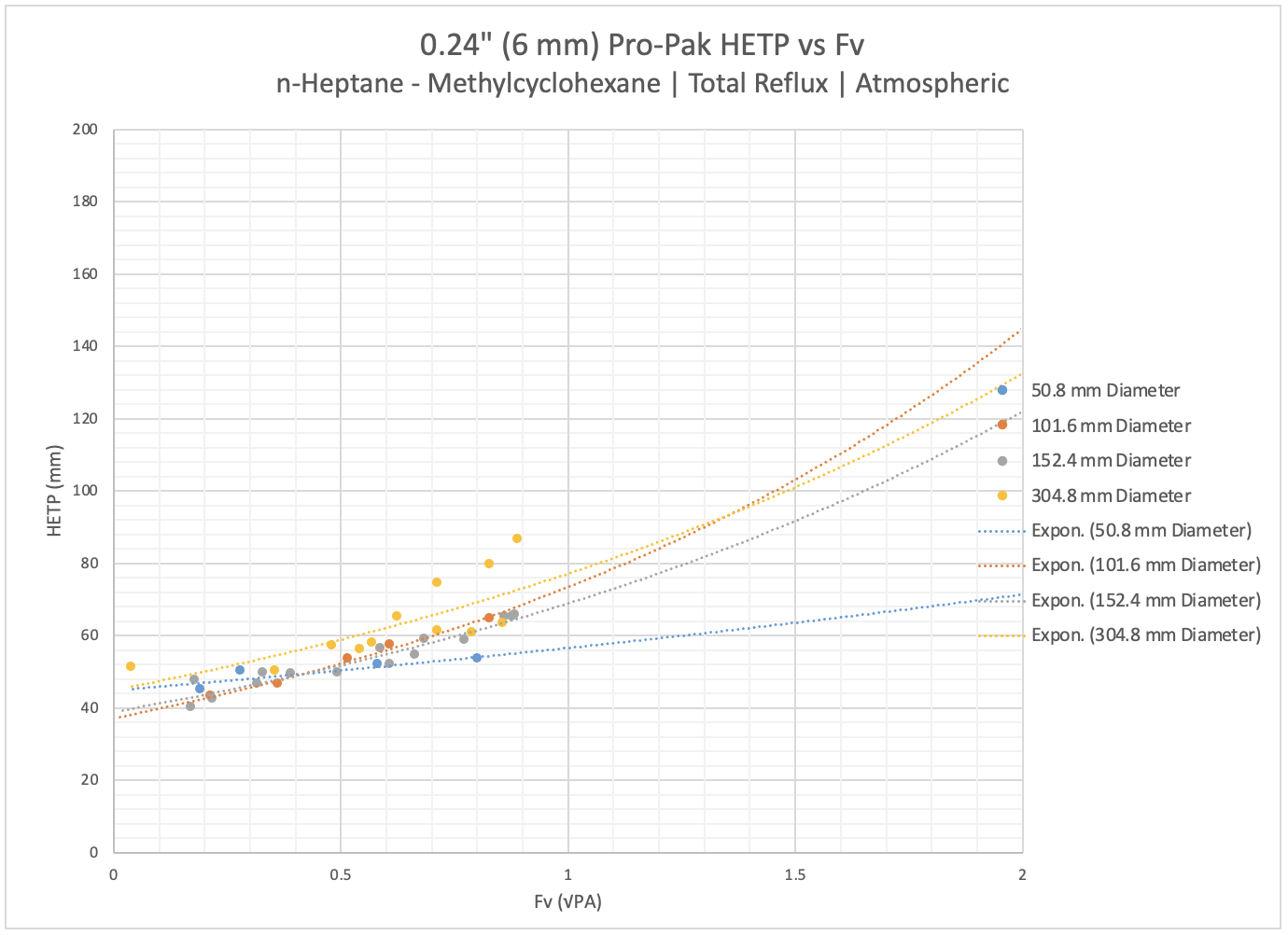

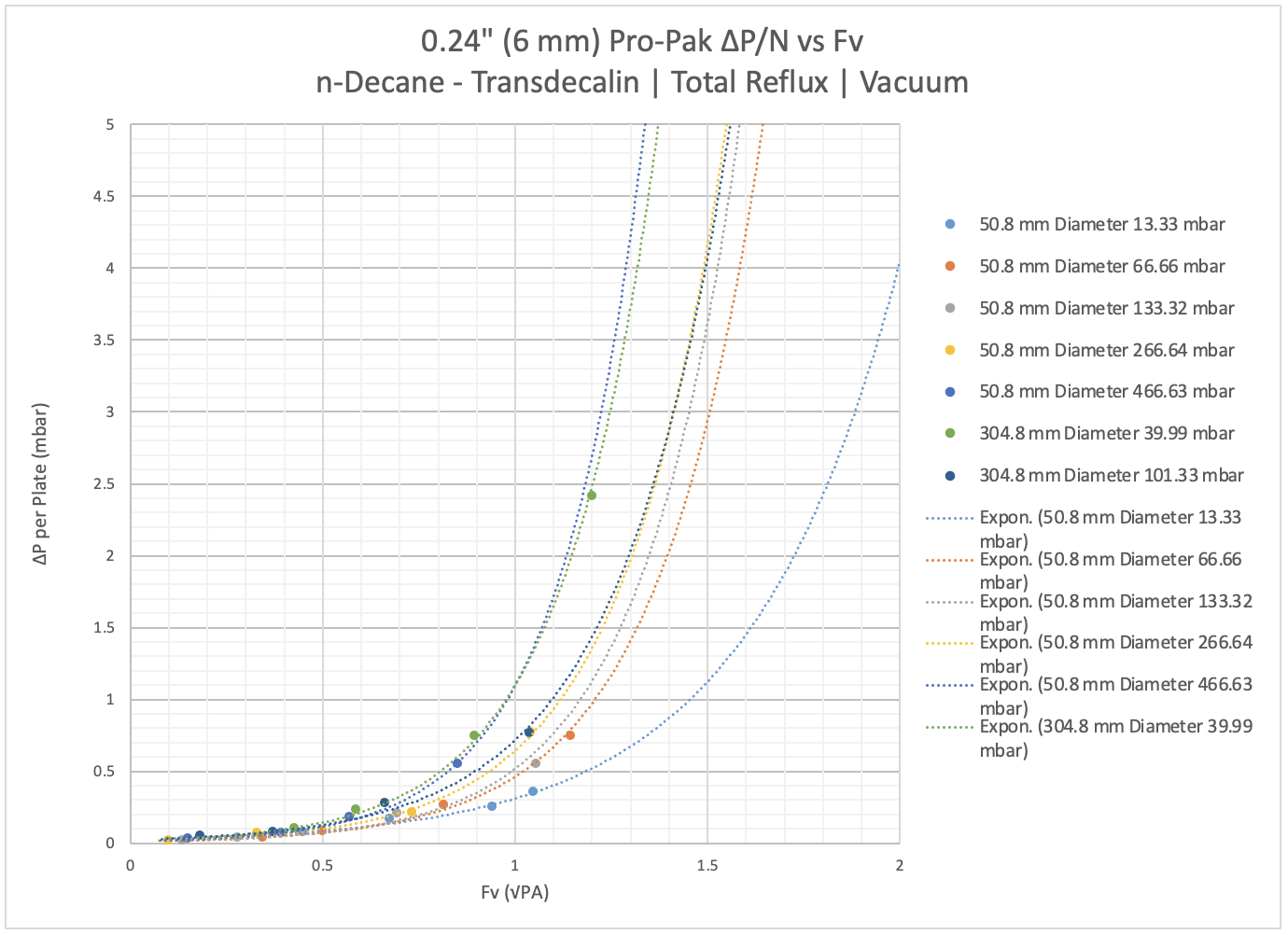

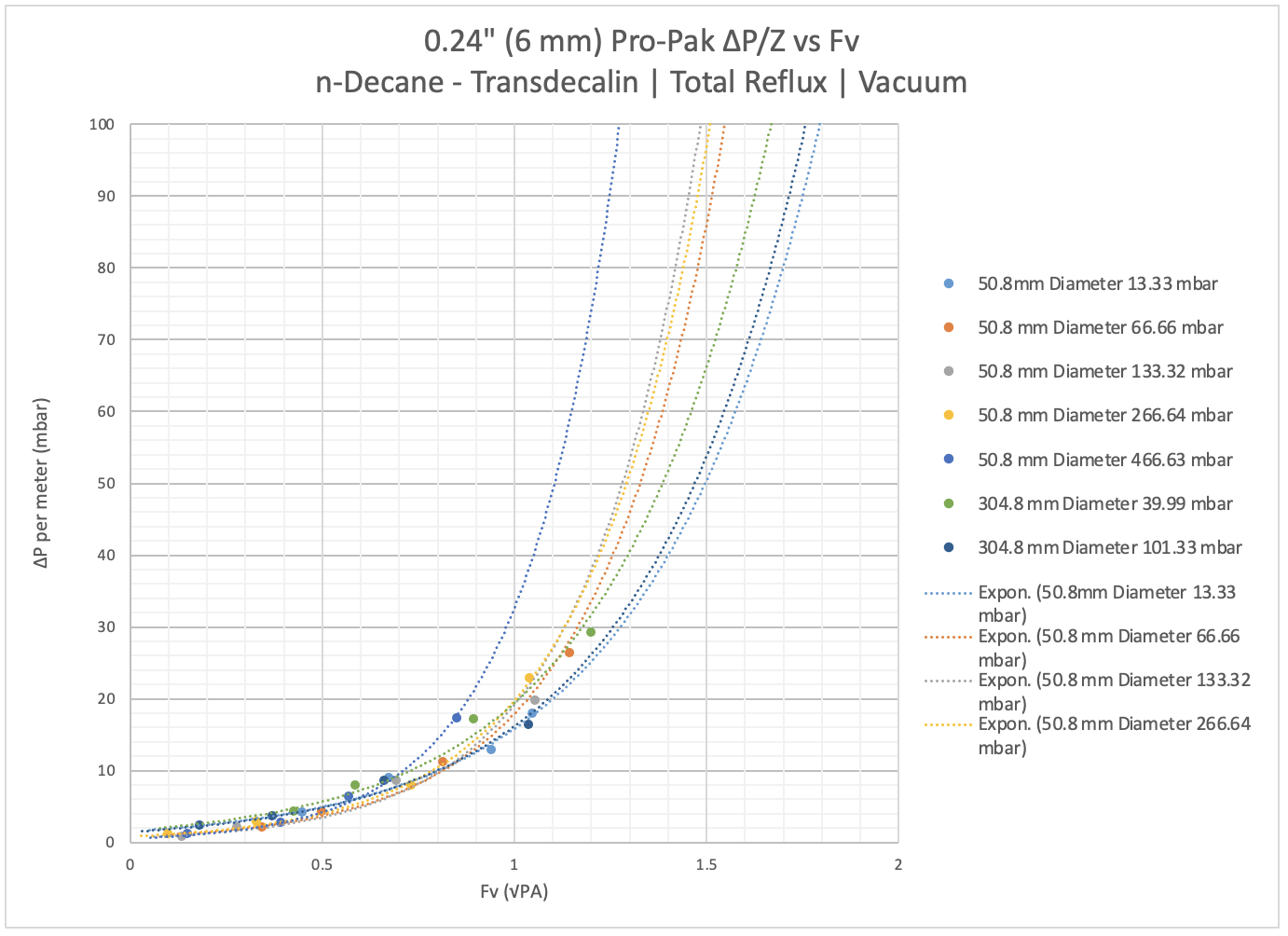

Our flagship product, Pro-Pak®, is a high-efficiency random packing designed for use in distillation. Effective in both atmospheric and low-pressure conditions, our packing meets stringent international standards, such as ASTM D2892, for the distillation of crude petroleum. Pro-Pak is available in two sizes, enabling high-efficiency separations in equipment ranging from bench research to pilot-scale operations and technical-scale production processes. Pro-Pak is extensively utilized where high purity, space-saving, energy-saving, and/or low loading are critical design considerations. Industries that have benefited from Pro-Pak include, but are not limited to, petroleum, food and beverage, organic chemistry, new materials/green chemistry, electronic chemicals, and isotopes.

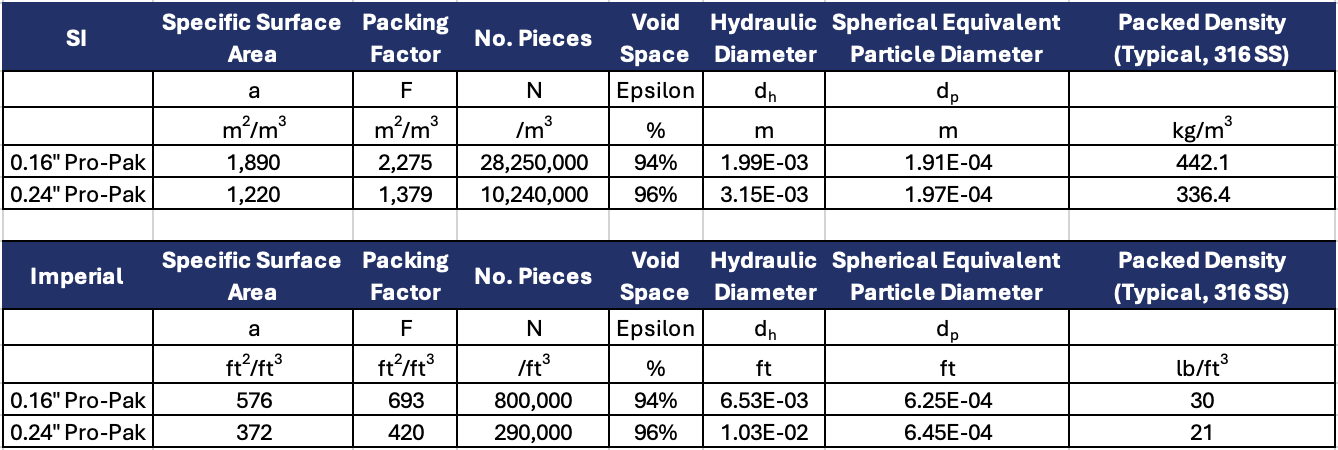

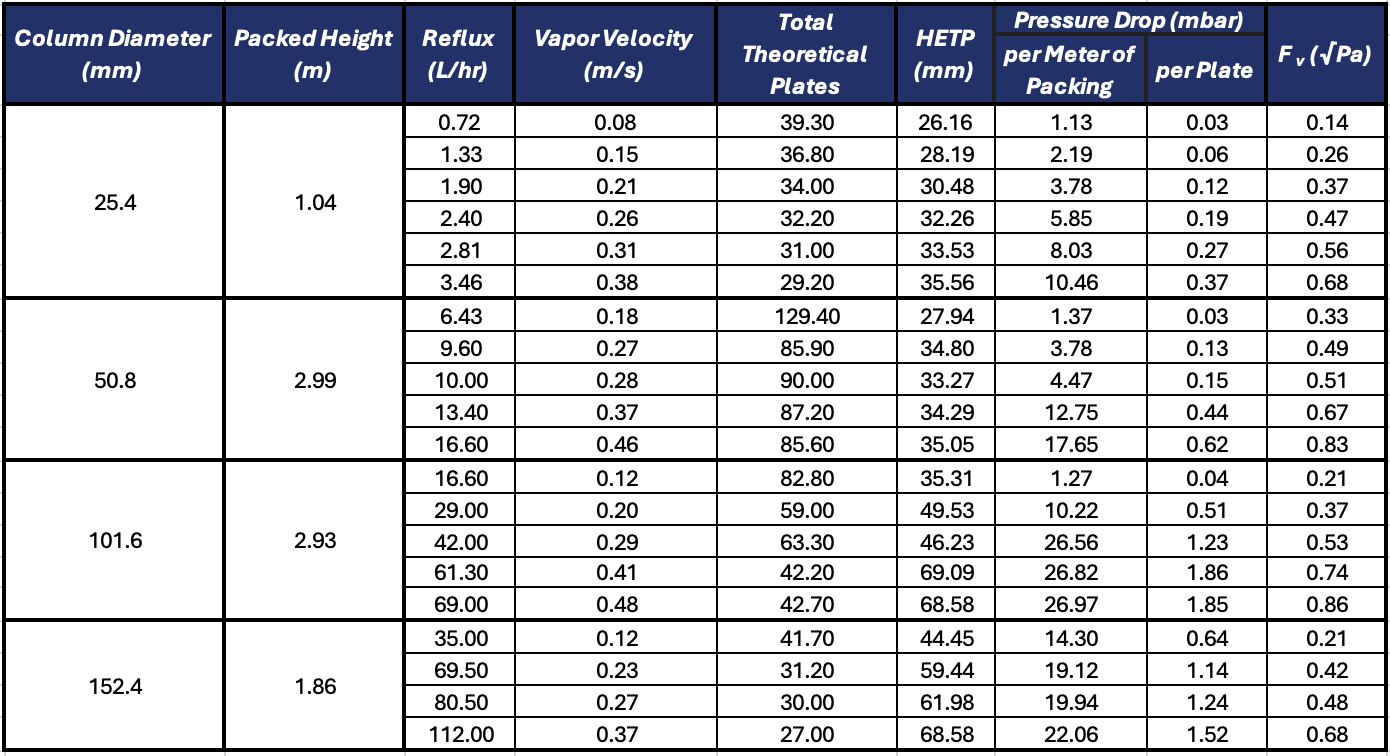

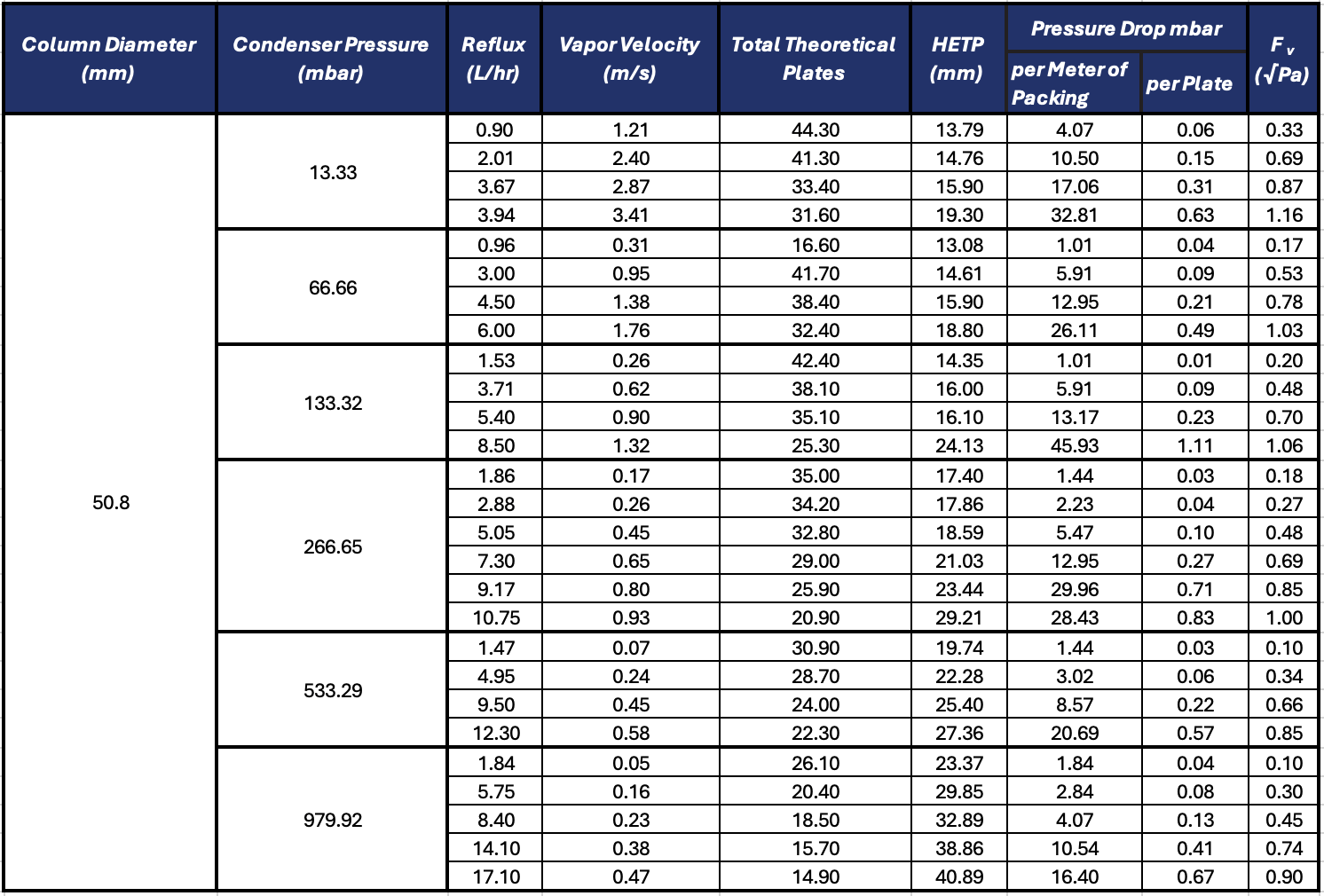

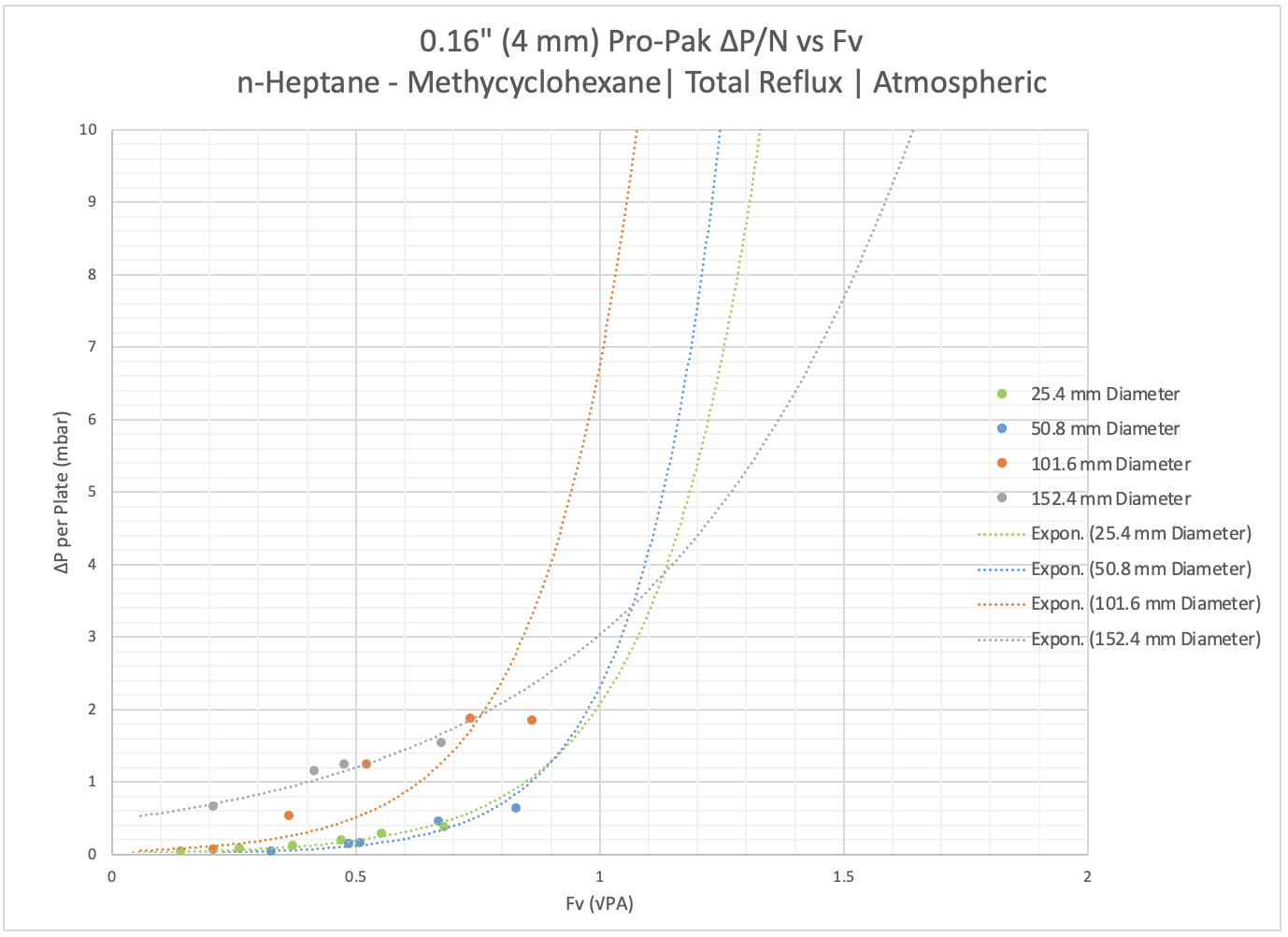

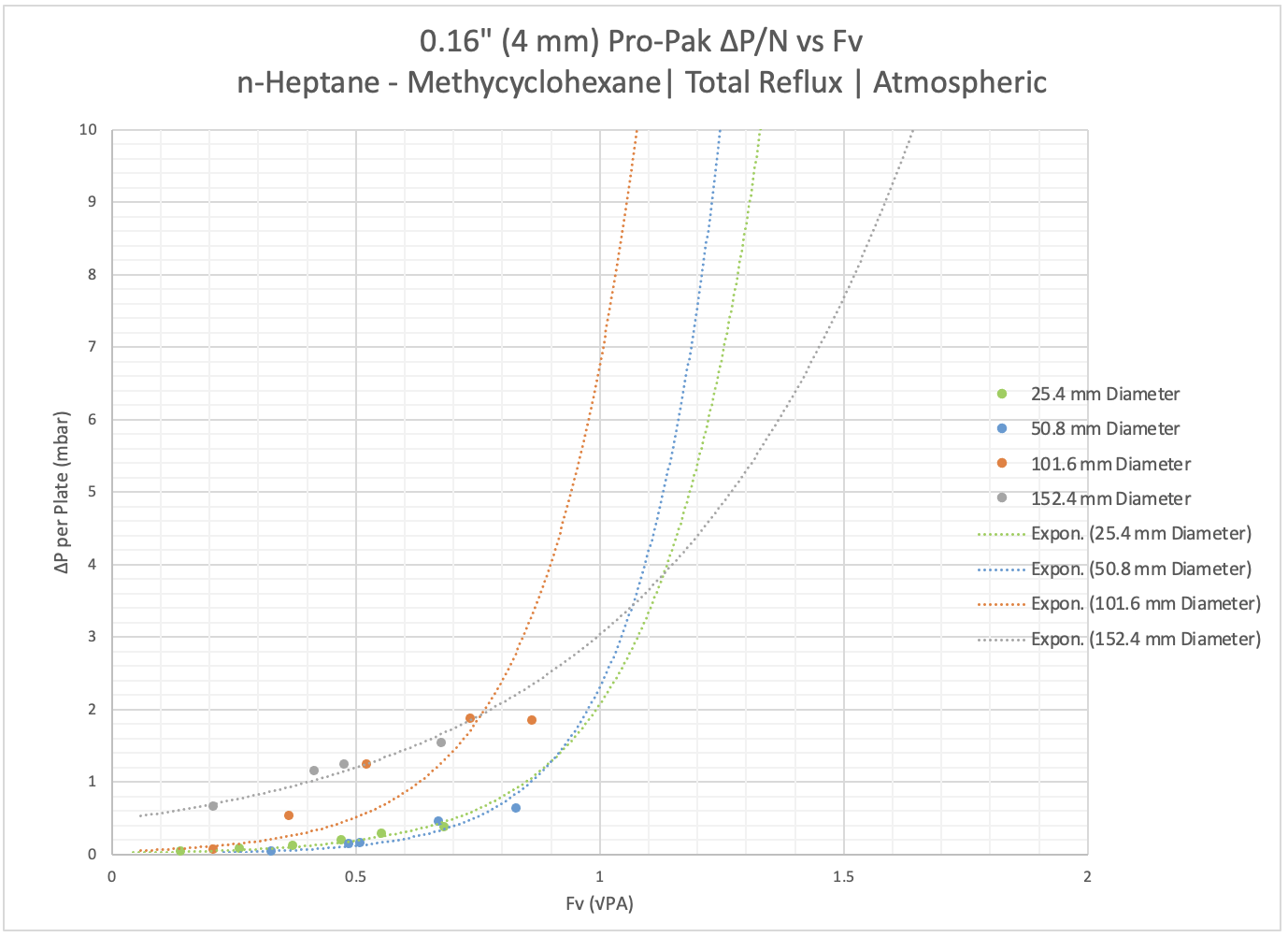

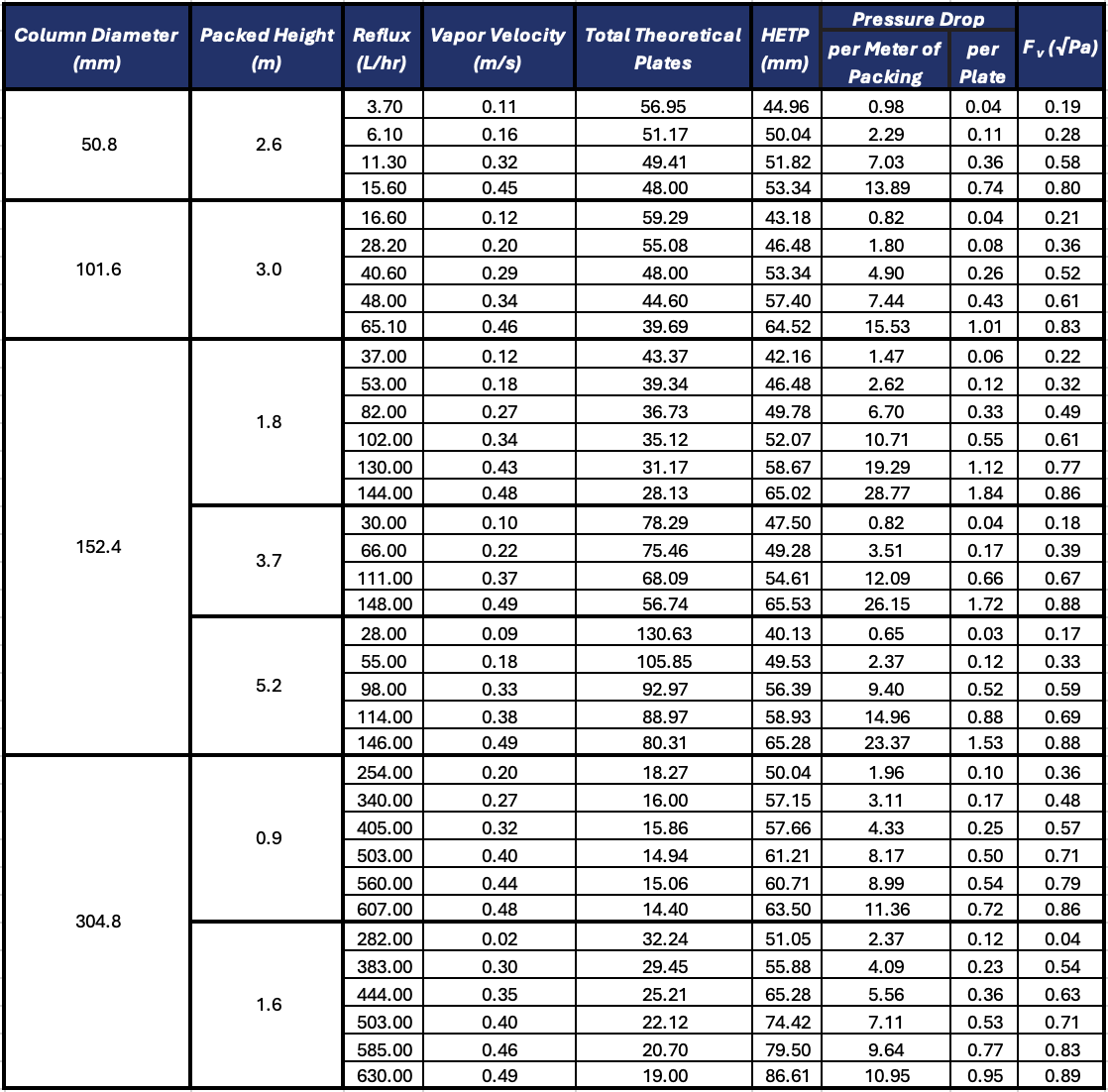

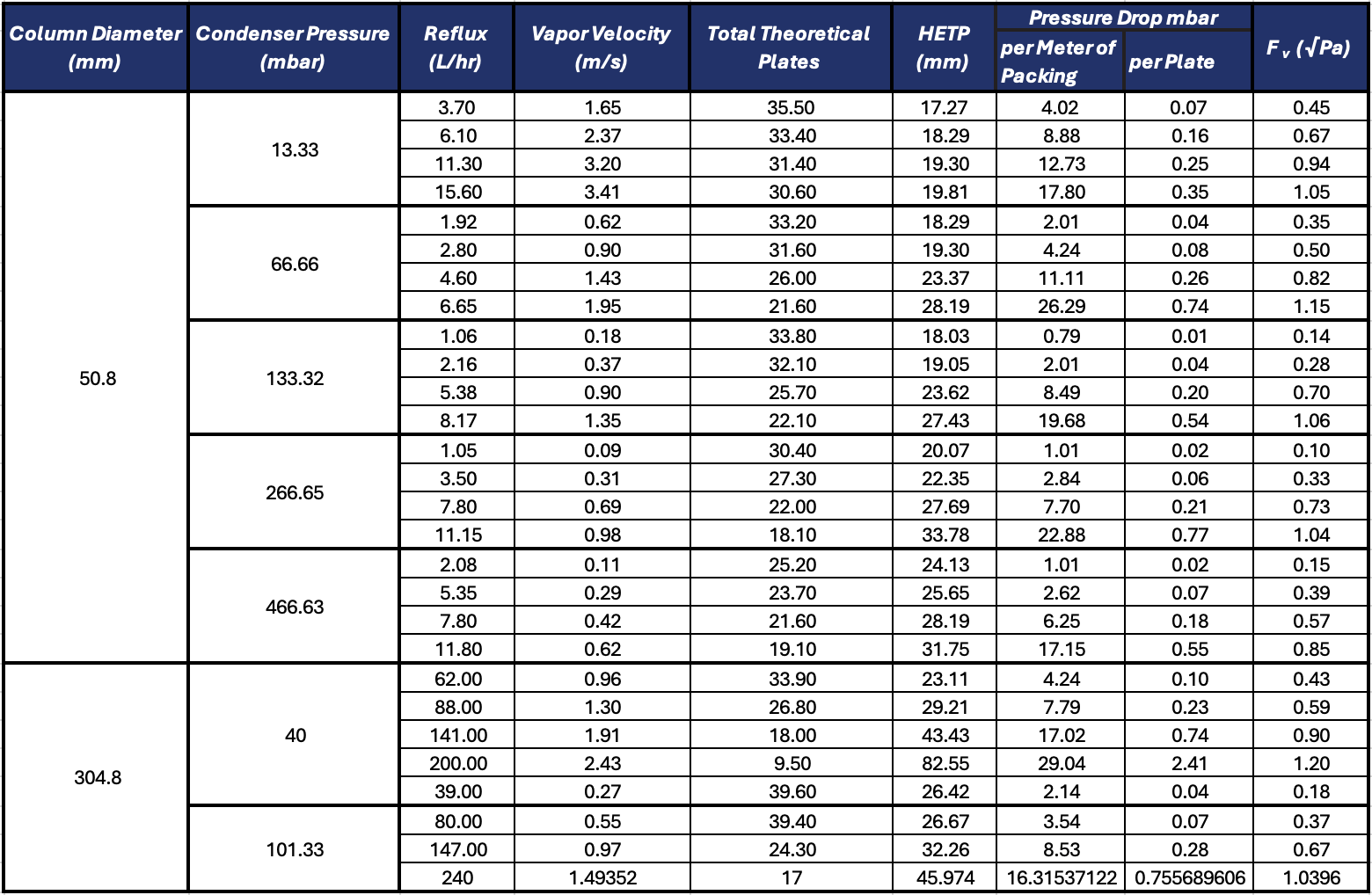

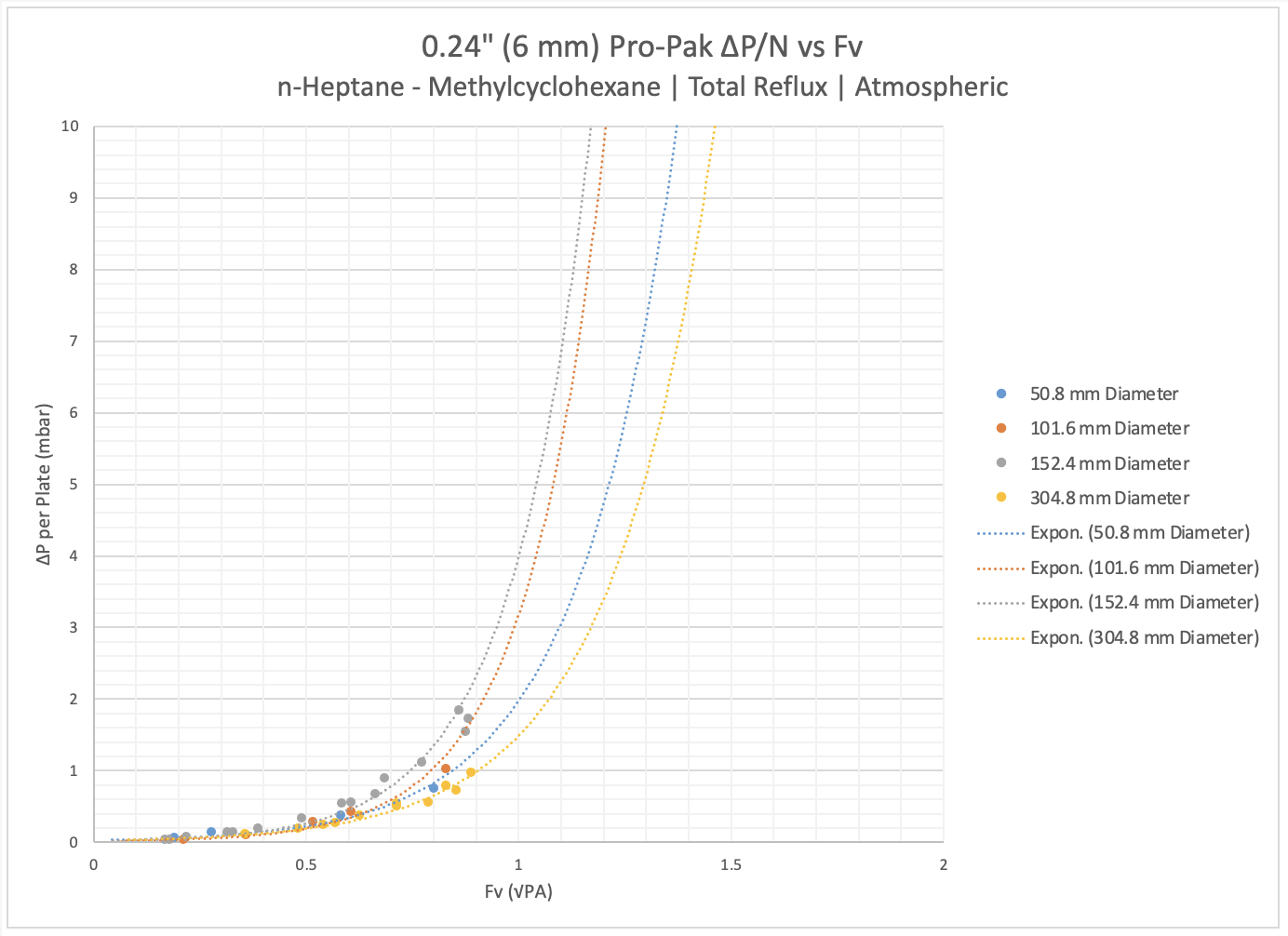

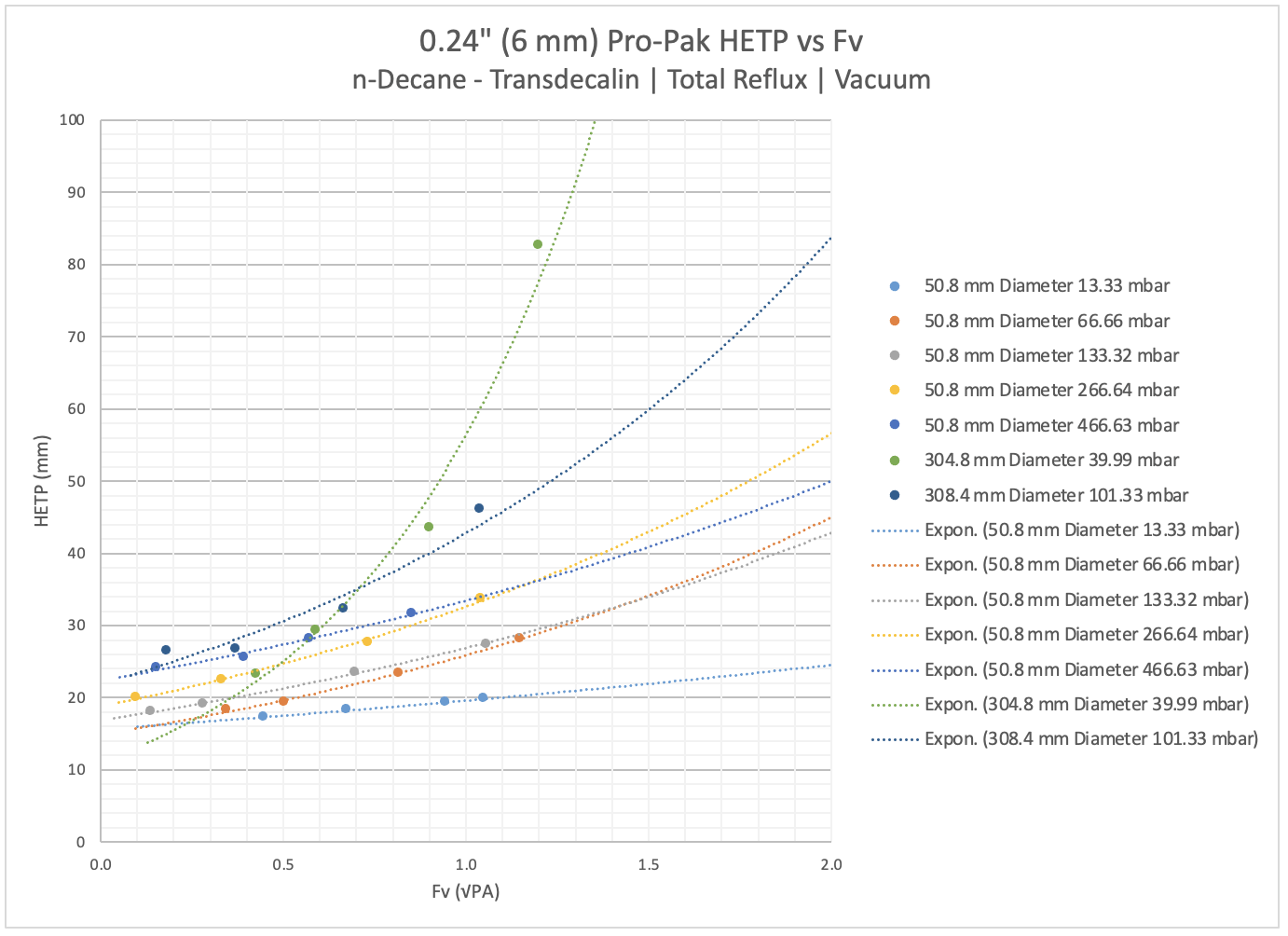

How our Pro-Pak® distillation column packing material measures up: